Search This Supplers Products:Industrial inkjet printer for Imaje Willett Videojet inkjet printerImaje Videojet Domino inkjet printers high quality small character ink and make upDomino Videojet Linx Imaje industrial inkjet printers low price cij ink fitersDomino Videojet Linx Imaje small character inkjet ink and make up manufacturerDomino Videojet Linx Imaje continue inkjet print head partsDomino Videojet Linx Imaje coding marking printer parts

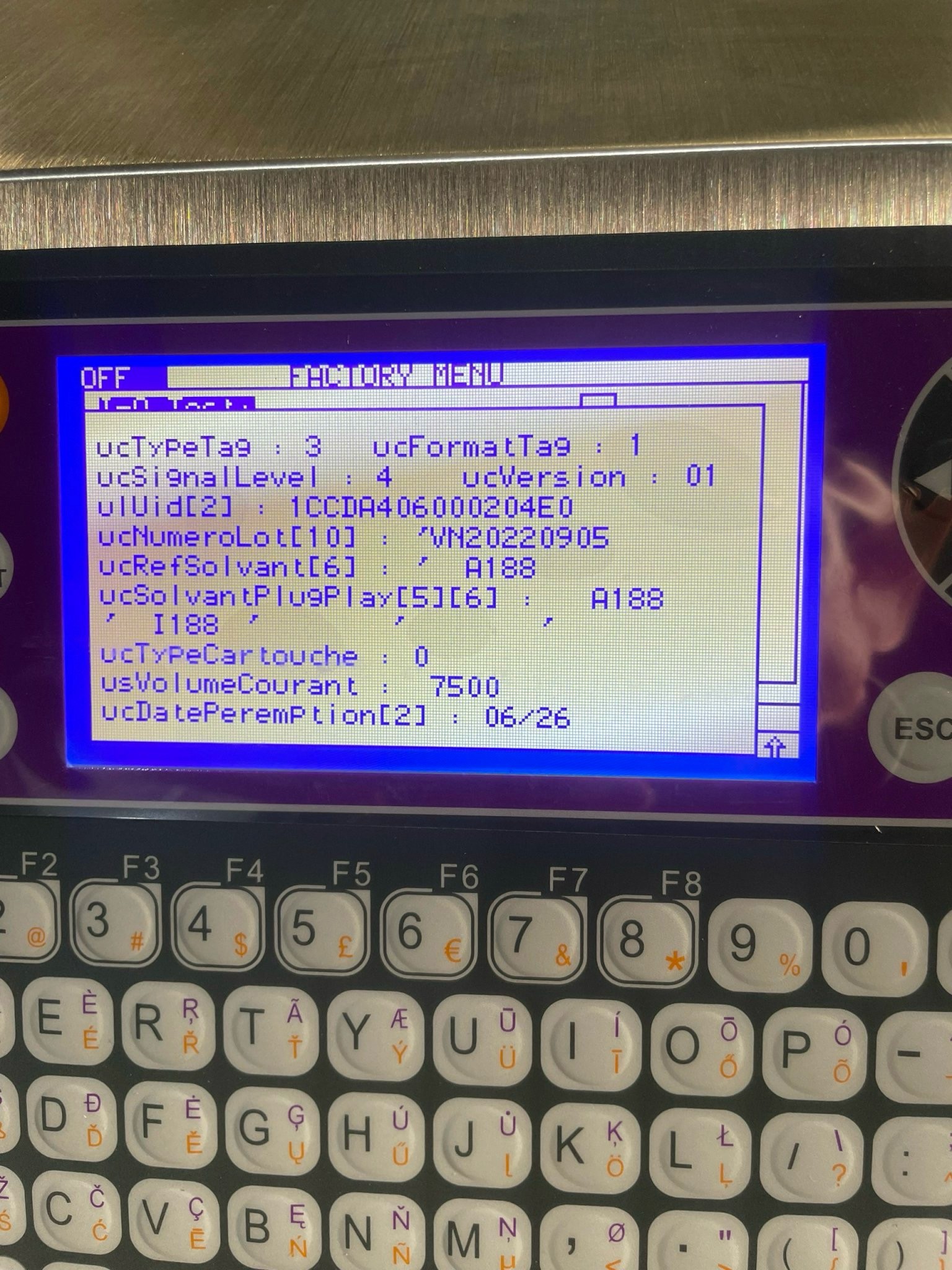

Markem-Imaje solvent A188 usVolumeCourant7500

This is 9028 printer Additive still has but printer alarm empty .

This is chip lot 6/26 but show 7500MM.

When install A188 slolvent,the printer said it's just 7500MM ,not 8000MM.Customer may thinking why just 7500MM. A188 solvent ,the bottle has the label tell us it's 8000MM,where is the short 500MM? Did the supplier short fill 500MM to the bottle?

Dont worry. The data 7500MM ,is correct.The chip liquid level is 7500-8000, which is a random display and actually has redundancy. With this chip, the machine can actually tank 10000MM.

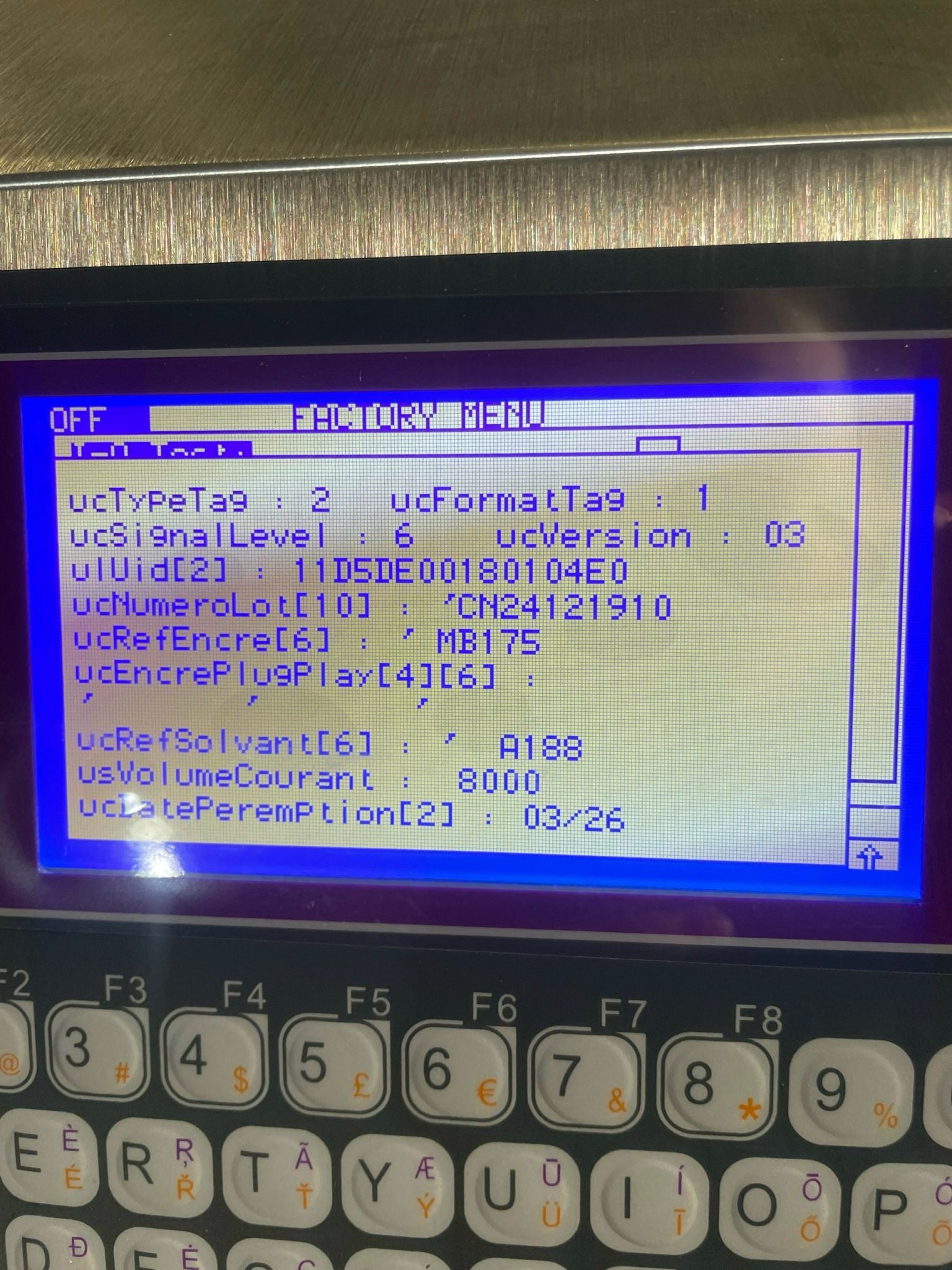

This is the chip lot 3/26 but show 800ML .

If the solvent pump woorking function is no good,will also affect the solvent data .

How this thing happpen ?Below ,it's 4 ways:

NO.1 :The outlet of the 9028 9029 9450 additive pump has a filter. When performing maintenance, it is necessary to replace the filter or clean it with ultrasonic waves before reinstalling it. If the filter is not replaced, it will affect the power of the pump. The substitute additive will have more impurities than the original one, which are pigments.

NO.2: The substitute solvent has a larger particle size and will block the filter in front of the pump, so it is better to use colorless additives

Their colors are just to distinguish models and look good. Additive pumps are more damaged than ink pumps A bottle of ink can be used for a long time, but the ink pump works less frequently.

Their colors are just to distinguish models and look good. Additive pumps are more damaged than ink pumps A bottle of ink can be used for a long time, but the ink pump works less frequently.

NO.3:The sealing of the solvent bottle mouth is not tight enough, and if it is often removed and installed, it will affect the data. If the air and additives are pumped together, it will affect the data.

NO.4:If the bottle is too hard and the pump efficiency is low, it will be even more difficult to pump the solvent into the machine